Refrigerants transport heat energy and thus represent the central operating material of all refrigeration, air conditioning and heat pump systems. But they can vary in terms of their fluid characteristics and thermodynamic properties such as energy efficiency – in some cases significantly. No single refrigerant is suitable for all applications. There’s also the fact that some refrigerants are toxic and/or flammable, others have a high global warming potential (GWP), and the CFCs and HCFCs banned in developed countries damage the ozone layer. Choosing the right refrigerant therefore has a role in determining whether systems are economic, environmentally friendly and efficient.

Reducing CO2 emissions

Most refrigeration systems release CO2 into the environment. These emissions are classified as either direct as a result of a leakage (corresponding to the CO2 equivalent of the refrigerant) or indirect through system energy consumption. The relationship between direct and indirect emissions can be very different depending on the type of energy generation, system design and operation mode, as well as refrigerant and rate of leakage and recycling. When it comes to the primary energy generation technologies used around the world, indirect CO2 emissions throughout the system’s life cycle are the most dominant by far.

When using refrigerants with a very low GWP, indirect emissions are almost entirely responsible for any impact. Crucial progress in environmental protection can therefore be achieved through the use of refrigerants with a low GWP and, in particular, with improvements to system energy efficiency, including measures for exploiting the waste heat of refrigeration systems for space heating and service water warming. For the system operator, this means future-proof, sustainable technology, reduced operating costs and a much smaller carbon footprint.

Not ambitious enough: the first EU F-gas Regulation

The EU’s F-gas Regulation 842/2006, which was in force between 2007 and 2014, aimed to reduce refrigerant emissions by providing for optimised recovery as well as improved containment through routine tightness checks, among other things. But the real impacts of these measures were insufficient to achieve the European Union’s (EU) ambitious climate targets. As a result, the EU made the decision to adopt a more stringent F-gas Regulation with use restrictions and refrigerant bans and thus intensify the requirements surrounding tightness checks.

Effectively reducing refrigerant consumption: the EU’s new F-gas Regulation

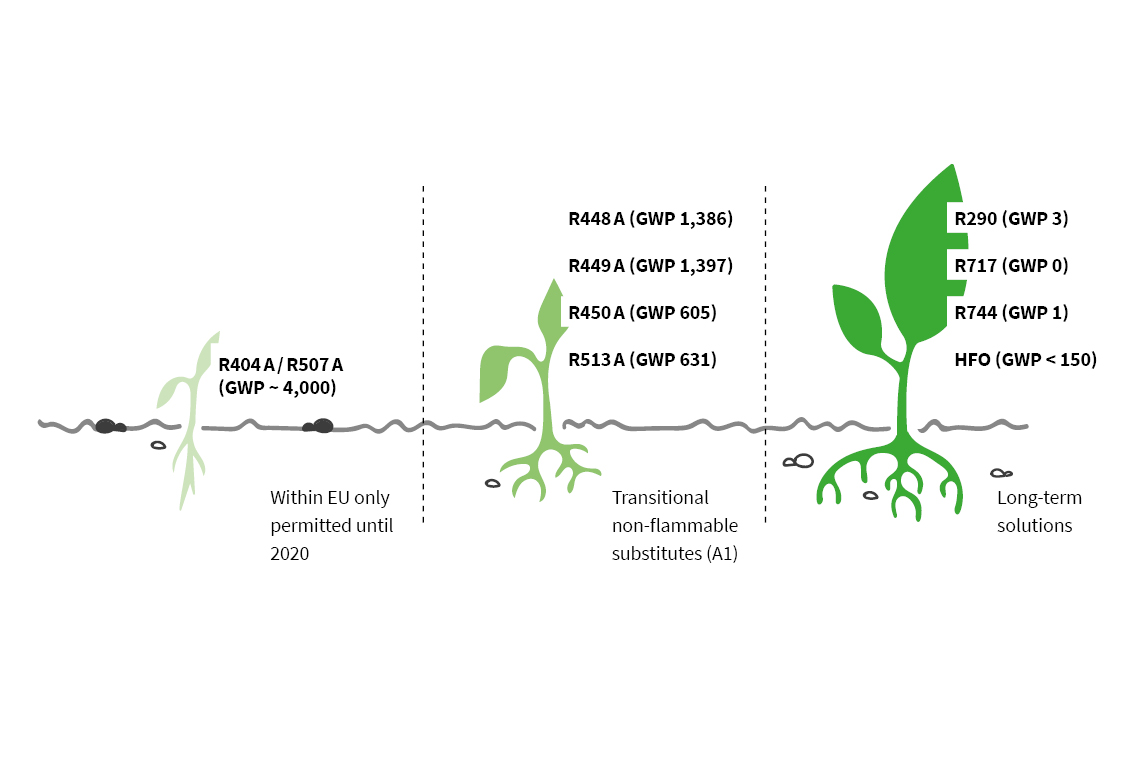

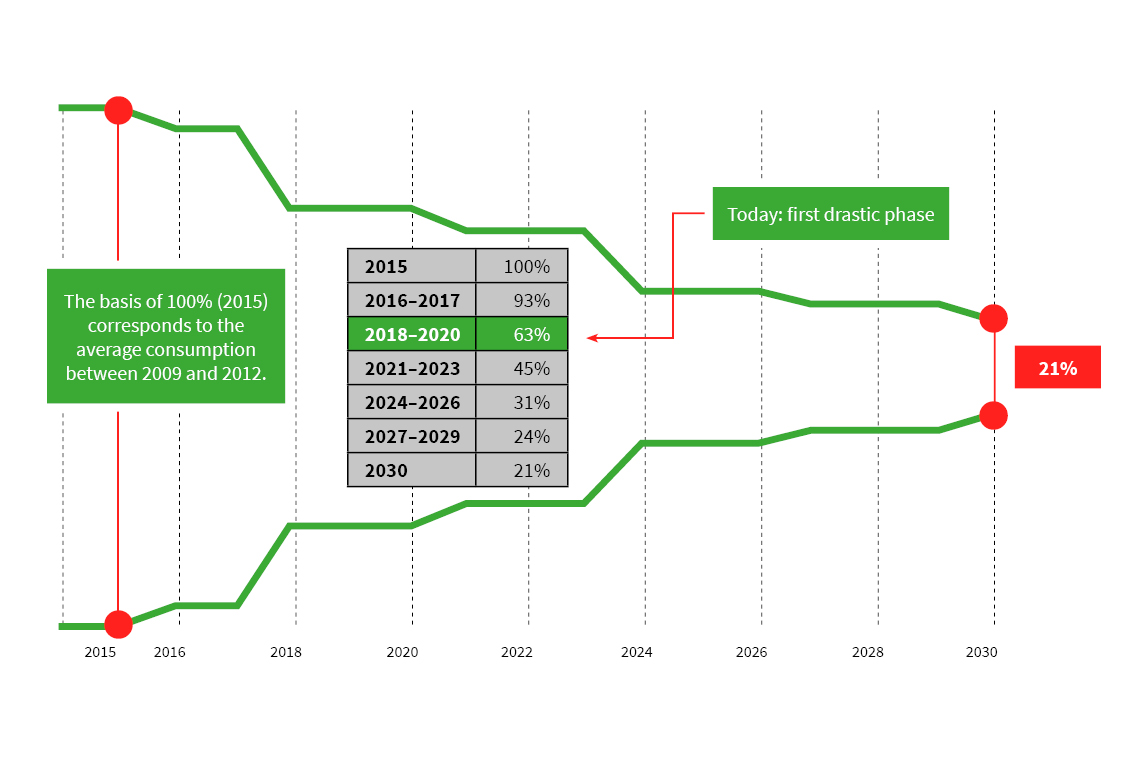

The primary feature of the F-gas Regulation 517/2014 is the “Phasedown” of the overall quantity of F-gases (partially fluorinated hydrocarbons) available. This quantity is defined in metric tons of CO2 equivalent – as a product of refrigerant quantity and the respective GWP. This quantity will be reduced to just 21% in several stages by 2030 (basis of 100% in 2015) and managed and monitored with a quota system to be applied by manufacturers and suppliers of refrigerants. What makes the situation more difficult is the fact that, as of 2017, systems pre-charged with F-gases pre-filled (air conditioning units, heat pumps, chillers) which are imported from countries outside the EU are also subject to the quota system. In the meantime, the freely available total quantity of F-gases has been reduced by this amount (approximately 12%), meaning the reduction stages are actually much larger than the requirements based on the reference value for 2015.

Examples

- 2018: quantity reduction (CO2 equivalent) 37%, actual approximately 45%

- 2021: quantity reduction (CO2 equivalent) 55%, actual approximately 60%

Expensive refrigerants

The F-gas Regulation has already made a significant economic impact. Due to the quota system and future use restrictions, key manufacturers are in the process of significantly reducing or even discontinuing the production and sale of refrigerants with a higher GWP, thus making them much more expensive. In some cases, the prices of the HFC refrigerants most commonly used in commercial systems have increased tenfold,* making them economically infeasible for many end users. Much of the time, availability can no longer even be guaranteed.

* Source: Monitoring of refrigerant prices against the background of Regulation (EU) No 517/2014: Ökorecherche, CITEPA 01/2019

BITZER is always optimising its compressors and, long before the F-gas Regulation took effect, introduced products which can also be operated with newly developed low-GWP refrigerants such as HFOs and HFO/HFC blends. This among other things is a key benefit when it comes to converting existing systems – compressors can then be adapted to meet special requirements with little effort. In the case of new systems or when switching to a new refrigerant, the compressors can then also be equipped or retrofitted with the innovative IQ modules for operating integrated functions. In addition to ensuring higher availability through intelligent monitoring and control, system performance can be adapted to specific needs. This makes operations especially efficient and, also for existing systems, reduces operating costs as a result of lower energy requirements.

Natural alternatives

Naturally occurring refrigerants such as CO2 (R744), ammonia (R717), propane (R290) and propylene (R1270) are not affected by the F-gas Regulation and other national and international stipulations on quantity reduction and use restrictions associated with refrigerants. Thanks to a GWP between 0 and 3, they fulfil all future requirements. However, using them demands special safety measures, as known, because they are flammable (propane, propylene) or toxic (ammonia). While CO2 is not toxic or flammable, the systems operate with very high pressures, which in turn necessitates special safety requirements, system technologies and correspondingly trained employees. BITZER customers benefit from extensive experience and training courses on using natural refrigerants offered all over the world by the refrigeration and air conditioning specialist.

Environmental protection: an international undertaking

Refrigeration, air conditioning and heat pump technologies are also subject to environmental regulations outside of the European Union. Similar stipulations are currently in the pipeline or have already been introduced in Australia, Canada and the US. On an international level, the Kigali Amendment was adopted in 2016 under the framework of the Montreal Protocol, which stipulates an HFC phase down beginning in 2019.