The provincial capital of Kunming with its 6.7 million inhabitants relies on BITZER compressors for an additional CO2 application: they manage the temperatures of the giant cooling area at Wanton Mall. The mall’s low temperature refrigeration area alone provides room for 100,000 tonnes of goods. In addition, almost 2,000 refrigerated display cabinets are installed in the shopping and event centre.

The figures from another Wanton Mall with BITZER solutions are even more gigantic. The major city of Wuhan has 7.5 million inhabitants and is situated around 840 kilometres inland to the west of Shanghai. In this metropolis, Wanton Mall has a refrigerated storage facility with a volume of 500,000 tonnes and with 3,740 refrigerated cabins.

The mall unites extremely diverse sectors with many special requirements under one roof. In the shopping and business centre there are food retailers, hotels, restaurants, corporate headquarters, exhibition centres, leisure and entertainment facilities and much more. The planners also thought big in terms of cooling capacity. When the project in Wuhan is completed, it will be the largest, most modern and most intelligent cooling chain logistics platform in the world.

Seven megawatts of cooling capacity

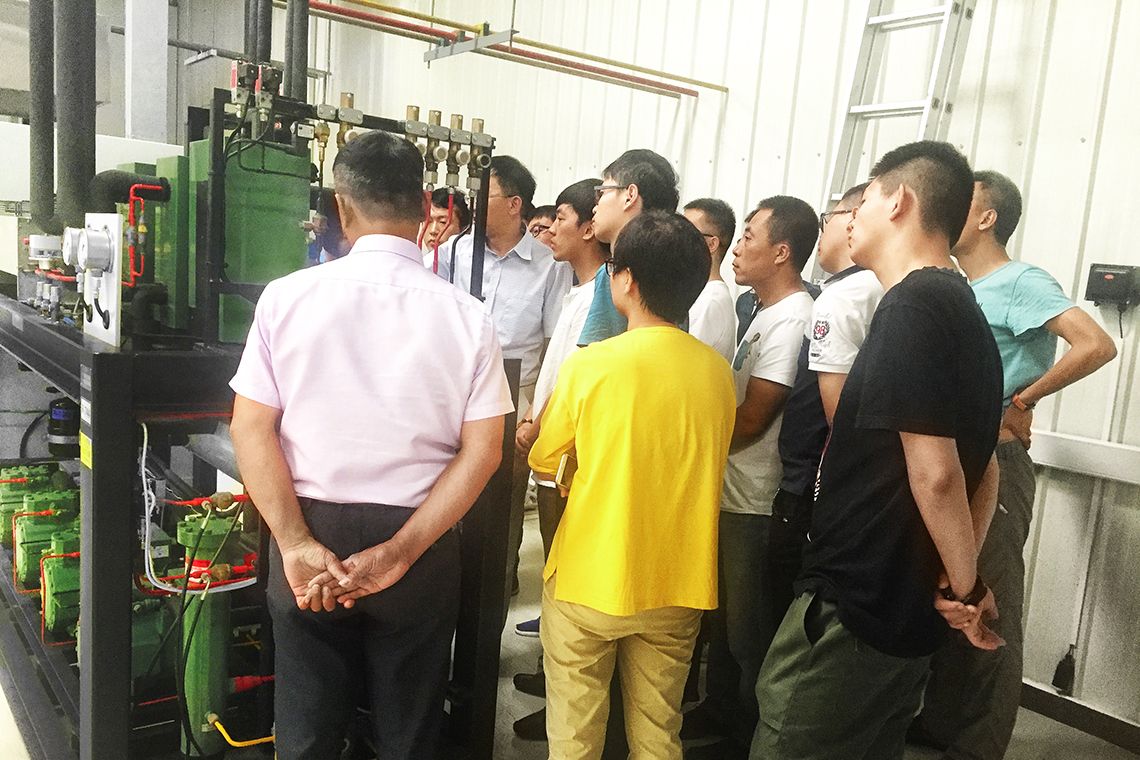

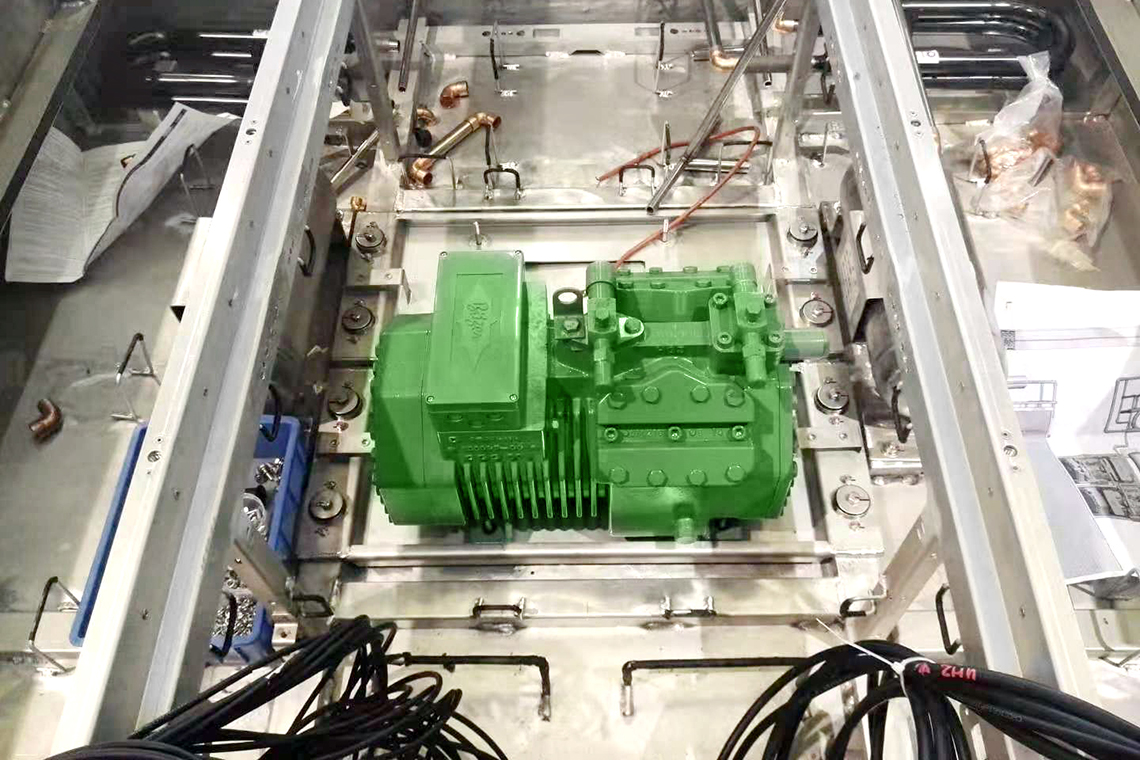

In both projects the Chinese installers from Jinan Dasen Refrigeration Engineering placed great emphasis on eco-friendly solutions and mounted R134a/R744 cascade systems. ‘In order to reliably manage the temperature of the refrigeration areas for the projects in Kunming and Wuhan, which together hold a total of 600,000 tonnes, the contractors from Jinan Dasen Refrigeration Engineering installed five CSVH and 40 CSH compact screw compressors as well as 79 reciprocating compressors for CO2 applications by BITZER.

Together, the compressors in Wuhan and Kunming generate a cooling capacity of seven megawatts,’ says Bill Feng. ‘The large number of CO2 compressors ensure that the systems are efficient and environmentally friendly. In addition to these two arguments, the planners were especially impressed by the reliability of BITZER compressors. With a system of this size, you can’t make any compromises when it comes to quality. With these dimensions, a system failure would be fatal.’

100.000

tonnes are covered by the low-temperature refrigeration area at Wanton Mall in Kunming, where BITZER compressors are deployed for cooling.

Complete heat recovery thanks to central control

The size of the central refrigeration area in Wuhan is also groundbreaking in the industry with around 3,700 refrigerated display cabinets and a volume of 200,000 tonnes. Service technicians monitor and control this system via the cloud – conveniently, safely and efficiently. The precisely tailored control system reduces the loss of heat in the individual refrigerated display cabinets in the shopping centre, which makes the almost complete heat recovery possible. In addition, central refrigeration improves the effective cooling capacity and saves more than half the amount of electricity in comparison to separately refrigerated cabins.

79

reciprocating compressors and

40

CSH compact screw compressors

from BITZER operate in the two Wanton Malls in Wuhan and Kunming

Utilising waste heat

Even the waste heat is utilised. The heat energy which results in Wuhan supplies hot water to the hotel integrated in the mall. ‘When fully utilised, the system can provide 15,000 litres of water per hour at a temperature of 85 degrees Celsius. The transcritical CO2 compressors also supply the heating system in winter. This means that the system achieves excellent coefficients of performance in refrigeration and heating capacity,’ explains Han Xing Wang, General Manager of the CO2 equipment manufactory ARCO Technology Co., Ltd. for the project. The heat accumulator installed in Wuhan can store up to 40 megawatts of energy and perfectly utilises the temperature difference between day and night. ‘The two malls in Wuhan and Kunming were a great challenge but an even greater success,’ says Li Xiao Hu, CEO of Internal Trade Engineering Design & Research Institute which designs and supervises these two Wanton projects. ‘The project partners joined forces extremely well. Together we demonstrated that efficiency and environmental protection are not a contradiction.’

15.000

litres of hot water at 85 degrees Celsius can be provided per hour by the system in Wuhan.