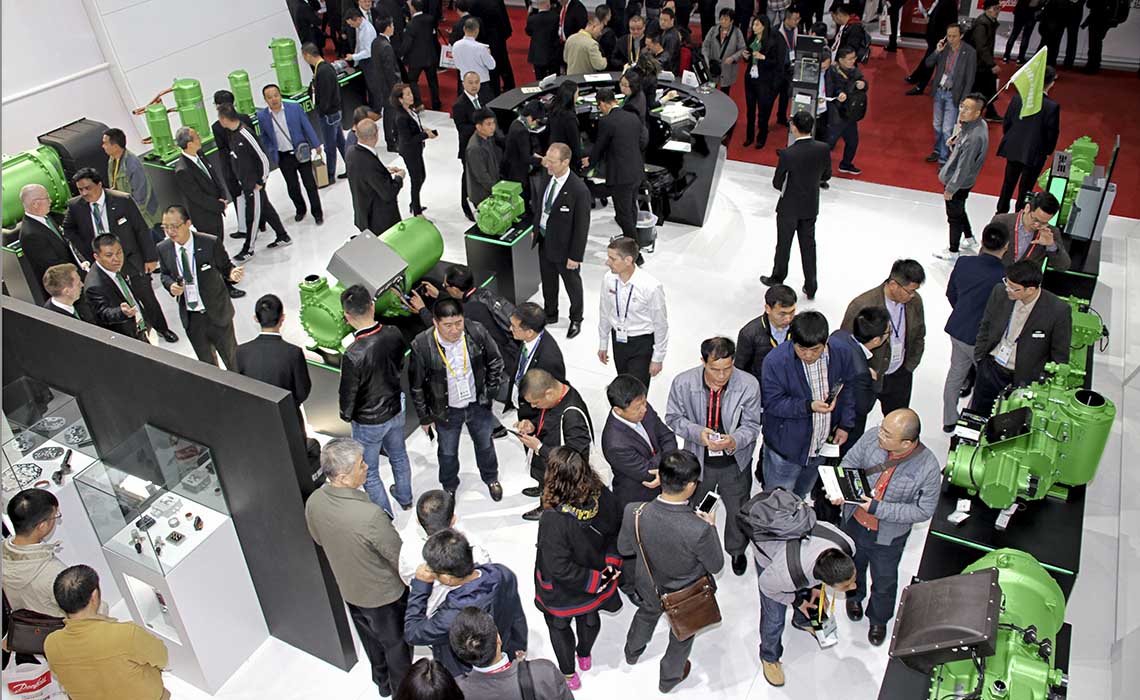

BITZER and China share a long history. In 1994, the compressor specialist founded its own subsidiary in Beijing, where it has been manufacturing for the Asian markets for nearly 25 years. The long-standing China Refrigeration trade fair, which was held for the 31st time in 2018, has long been a key event for BITZER: ‘For us, China Refrigeration is one of the most important trade fairs in Asia,’ explains Gianni Parlanti, Board Member and Chief Sales and Marketing Officer at BITZER. From 9 to 11 April, the world’s largest independent manufacturer of refrigeration compressors presented its new product highlights for the Chinese market.

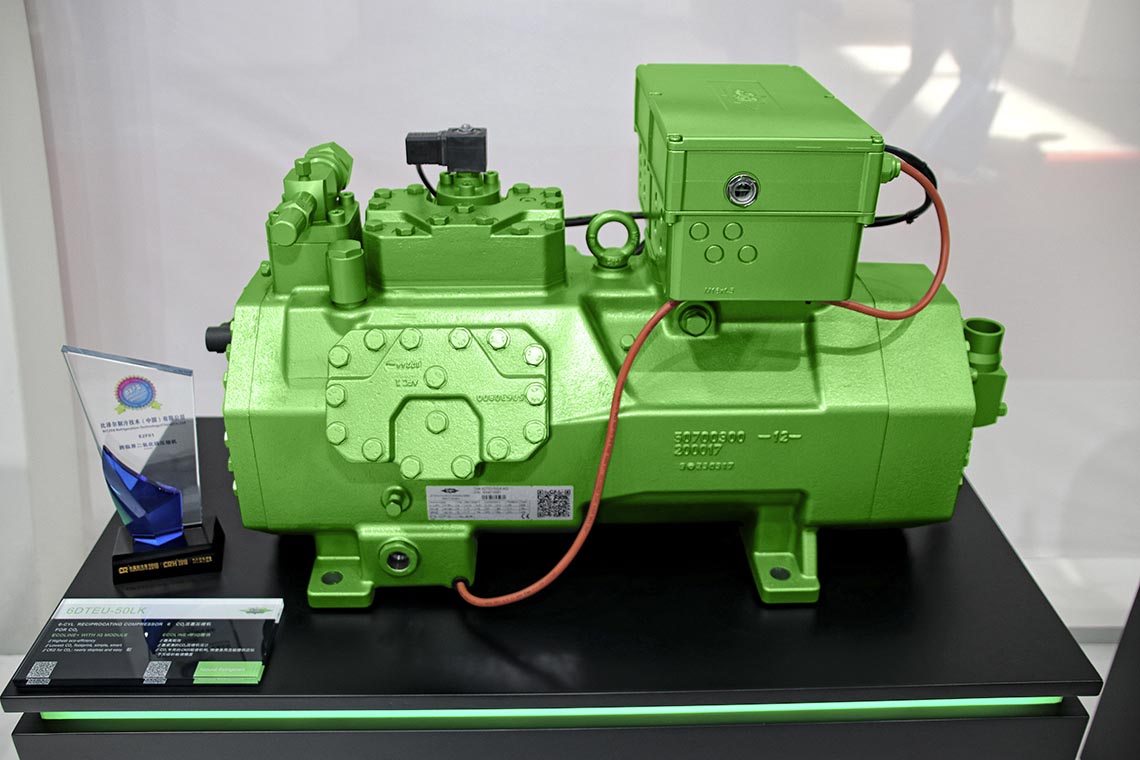

ECOLINE+ named ‘Innovation Product of the Year’

Its performance data impressed the specialist jury of the Chinese trade fair, which presented the ECOLINE+ compressors featuring IQ module with the China Refrigeration Innovation Product Award in the Refrigeration Component category. This is the second award that the innovative series has won this year: the ECOLINE+ reciprocating compressor had already received the renowned ACR News Award as ‘Refrigeration Product of the Year’ in January.

When you play the video, you transmit data to YouTube. For more information, see Data Protection

ORBIT scroll compressors

The compact ORBIT scroll compressors for air conditioning systems and heat pump applications offer unrivalled energy efficiency in full and part-load operation across all operating conditions. The key strengths of the tried-and-tested ORBIT 6 and 8 compressor ranges include compact dimensions and unique compound solutions. At China Refrigeration, BITZER presented for the first time the new ORBIT FIT (flexible injection technology) series, with which the compressor specialist expertly accommodates the Chinese efficiency standard GB19577:2015. The new ORBIT FIT compressors boast an optimised economiser and an extended operation diagram; the latter is advantageous particularly when used in heat pump applications.

The new ORBIT FIT scroll compressors are developed for flexible operation with frequency inverters in a range between 35 and 75 Hz, much like the ORBIT 6, ORBIT 8 and ORBIT+ series. In addition, they offer the quietest operation in their class and an oil carry over rate that is unique in industrial applications.

When you play the video, you transmit data to YouTube. For more information, see Data Protection

For flexible combinations

ORBIT 6 and ORBIT 8 scroll compressors feature corresponding dimensions and connections, making them easy to replace. The BITZER Advanced Header Technology (BAHT) system even allows contractors to connect uneven ORBIT compressors in tandem and trio units with just four pipeline units. Another key benefit is the BAHT oil management system, which simplifies the design, reduces manufacturing and operating costs and enables a whole host of potential combinations. Users therefore have complete freedom to put their systems together according to their individual requirements and can replace old compressors easily.

‘Efficiency, reliability and quality were the key issues in our industry for decades. But, as we all know, that has changed. New topics are gaining importance and shaping the agenda around the world. Challenges that BITZER acknowledged and accepted early on,’ says Gianni Parlanti, Board Member and Chief Sales and Marketing Officer at BITZER. ‘Today we’re the driver of innovation in the industry. Our intelligent and digital solutions are true milestones in refrigeration and air conditioning and thus future-proof. Also presented at China Refrigeration 2018, the CSW105 compact screw compressors are a shining example.’

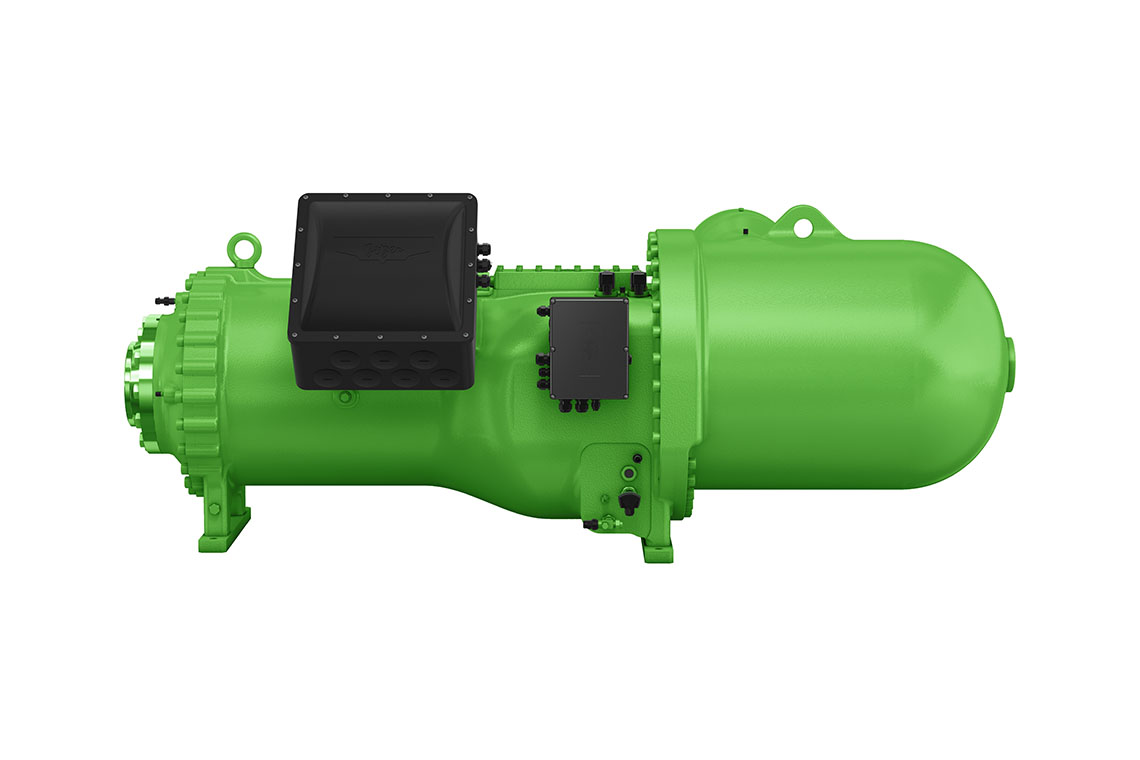

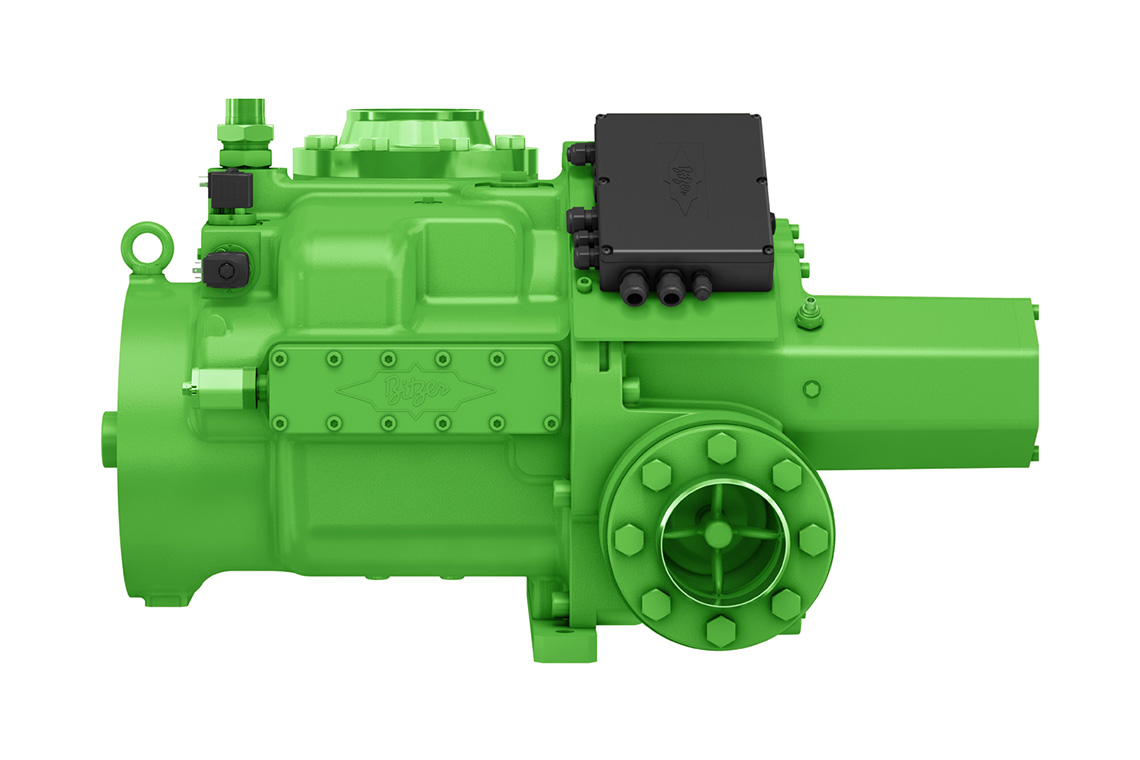

Intelligent and compact: CSW105 screw compressors

The CSW105 compact screw compressors offer cooling capacity of up to 1,500 kW in water cooled liquid chillers. The intelligent compressors also exceed by 200% the stringent energy efficiency grade of 1 of the Chinese standard GB19577:2015 for chillers. BITZER has developed the new models specifically for low condensing temperatures and a unique level of efficiency in full and part-load operation. The CSW105 compressors achieve a displacement of up to 2,000 m3/h at 50 Hz.

The new compact screw compressors are designed for use in air conditioning applications with the highly efficient R134a refrigerant. However, the compressors are also suitable for HFO refrigerant and HFO substitutes R1234ze(E) and R1234yf. The latter have a GWP of less than 10. The HFO/HFC blends R513A and R450A are also approved for the CSW105 compressors. With a GWP of around 600, they belong to the A1 safety group.

The integrated CM-SW-01 IQ module with prewired sensors and actuators makes it possible to affordably integrate the compressors into existing systems and ensures efficient and safe operation in the expanded map. BITZER’s new CSW105 compact screw compressors also feature stepless CR capacity control and an optimised slider concept for automatic Vi adjustment. The latter independently and efficiently controls the volume ratio in a wide application range.

Efficient with high pressure: CO2 compressors

‘For more than 20 years, BITZER has been developing and manufacturing compressors for subcritical and transcritical CO2 applications. This experience is key for solutions with R744, because, alongside efficiency and reliability, safety also plays an important role,’ explains Rainer Große-Kracht, Board Member and Chief Technology Officer at BITZER. ‘That’s because compressors that use the climate-neutral CO2 refrigerant with a global warming potential of 1 have to set standards when it comes to energy efficiency .’

Developed for supermarket applications, the ECOLINE+ reciprocating compressor series features an optimised line-start permanent-magnet motor (LSPM), which can be connected to 50 and 60 Hz grids, enables new levels of efficiency and increases annual performance figures by more than 10 per cent. Another key benefit is the VARISTEP mechanical capacity control for transcritical CO2 applications, as it offers a level of system efficiency which is otherwise only possible with a frequency inverter. So that users can fully exploit the potential of this innovative technology, BITZER has also developed a new operating concept with intelligent (IQ) modules. The IQ module means that the ECOLINE+ reciprocating compressors can be easily, quickly and cost-effectively integrated into a variety of system configurations. Apart from that, the IQ module improves the protective measures as well as the monitoring options for the compressors, allowing them to be used in a wider range of applications. This offers users more flexibility and makes it easier to compensate for the differences between summer and winter operation. The ECOLINE+ series is available as a four and six-cylinder compressor and boasts optimal efficiency in full and part-load.

The eight compressors of the CME series are designed for subcritical applications and are suitable as boosters and for use in water cooled systems in low and medium temperature applications. With a displacement ranging from 1.7 to 9.22 m3/h and with two different motor versions, the reciprocating compressors are exceptionally versatile and can be adjusted for all capacity requirements. At the same time, the new cylinder head facilitates an extremely low pressure pulsation. The CME series combines the proven efficiency and reliable drive gear technology of BITZER SL compressors with an exceptionally high strength of 100 bar standstill pressure, whilst maintaining operating reliability at all times. The CME series is also ideal for use with chilled water distribution networks with a maximum condensing temperature of 25°C.

Environmentally friendly and powerful: OS.A95 screw compressors

With its energy-efficient OS.A95 screw compressors, BITZER offers a climate-friendly and powerful solution for ammonia applications. The natural refrigerant has no global warming potential (GWP 0) and doesn’t damage the ozone layer. With their high cooling capacity and automatic Vi adjustment, the screw compressors are also suitable for a wide range of applications. BITZER has further optimised both the rotor profiles and the flow cross sections to ensure that OS.A95 models are just as suitable for air-conditioning and medium temperature applications as they are for the low temperature refrigeration range or heat pump applications.

The series boasts large displacements of up to 1,015 m3/h. The integrated BITZER IQ module enables precise, stepless capacity control in line with the superior system controller. A key component of the OS.A95 series is the integrated double slider, which can be used to efficiently and infinitely adjust the compressor’s cooling capacity and internal volume ratio in a wide range of applications. The IQ module adjusts the internal volume ratio automatically based on operating pressures. BITZER’s range of accessories also includes couplings and coupling housings.

Extensive application range

The ship classification society DNV GL has also certified the BITZER screw compressors in the OS.A95 series for use in marine refrigeration systems. As a result, those responsible can now choose from a large range of BITZER compressors approved for use in maritime applications. To obtain this certification, the specialist in refrigeration compressors in Sindelfingen had to verify the source and quality of the materials used, amongst other things.