The appearance of the specialist for refrigeration and air-conditioning technology at Chillventa 2018 can be described as BITZER times two: the long-standing company could be found by specialist audiences at two stands at the international trade fair in Nuremberg. The main trade fair stand, almost 688,5 m2 in size, featured BITZER reciprocating, screw and scroll compressors as well as condensing units and the new CO2 booster system for medium and low temperature applications. Just a few metres away from its central trade fair stand, the second BITZER stand presented products including water cooled condensers, dry expansion evaporators and liquid receivers.

When you play the video, you transmit data to YouTube. For more information, see Data Protection

EXPANDER: BITZER world premiere presented at Chillventa 2018

BITZER celebrated a world premiere at Chillventa 2018 when it presented the new EXPANDER unit. The subcooling unit is designed primarily for supermarkets and logistics specialists and improves both the energy efficiency and cooling capacity of transcritical CO2 refrigeration systems by over 20 per cent. ‘By integrating just one component, operators can improve the efficiency and capacity of their systems significantly, and that goes for both new and retrofitted systems’, explains Tobias Fuhrer, Product Manager Reciprocating Compressors at BITZER. ‘Installation is quite simple and there’s no need to redesign the refrigeration system, which can be a complex process. With the BITZER EXPANDER unit, CO2 can now be used efficiently as a refrigerant in hot climates.’ Combined with high-quality compressors such as ECOLINE+ reciprocating compressors, the subcooling unit represents a premium solution for outstanding eco-efficiency and optimised energy efficiency for transcritical CO2 systems. ‘The EXPANDER unit works a little like an external subcooler and can be integrated into a variety of CO2 systems easily and cost-effectively’, explains Fuhrer.

ALDI SÜD was impressed by the concept of the BITZER EXPANDER unit. The discounter is the first company to test the subcooling unit in its branches and continue implementing its environmentally friendly business policies. The operations of ALDI SÜD have been climate-neutral for years and it is now working to reduce its carbon footprint.

When you play the video, you transmit data to YouTube. For more information, see Data Protection

Seven new models at once – ECOLITE condensing units

BITZER has added a new series to its family of condensing units and presented the innovative models at Chillventa. The seven new ECOLITE condensing units are air-cooled and are designed for low and medium temperature applications and for a multitude of applications including cold stores, display counters and small shops. The three LHL3E condensing units have an internal fan and the four LHL5E models even have two fans. The seven models cover a wide range of applications from 1.5 kW to 5 kW in the low temperature refrigeration range and from 3.5 kW to 16 kW in the normal temperature refrigeration range, and are developed to operate extremely quietly. Their flexibility is one of their greatest strengths: ‘The adaptability of the ECOLITE models to various applications is outstanding,’ reports Stefan Dorn, Product Manager System Solutions at BITZER. ‘The reasons for this are the use of efficient components in combination with the VARISTEP capacity regulation for ECOLINE compressors as well as the fact that all models can be used for medium and low temperature applications.’

As with all ECOLITE condensing units, BITZER has fitted the new models with mechanical VARISTEP capacity control for stepless capacity adjustment of between 50 and 100 per cent. The ECOLITE condensing units have control software developed especially by BITZER and operate extremely reliably. ‘Users benefit from the fact that all of the components have been precisely coordinated and that the condensing units are very quick and easy to install and commission with their extensive standard equipment and plug-and-play concept’, says Dorn. ‘The entire series is Ecodesign-compliant and has been designed for use with common refrigerants. These also include refrigerants with low global warming potential (GWP) such as HFO mixtures.’

When you play the video, you transmit data to YouTube. For more information, see Data Protection

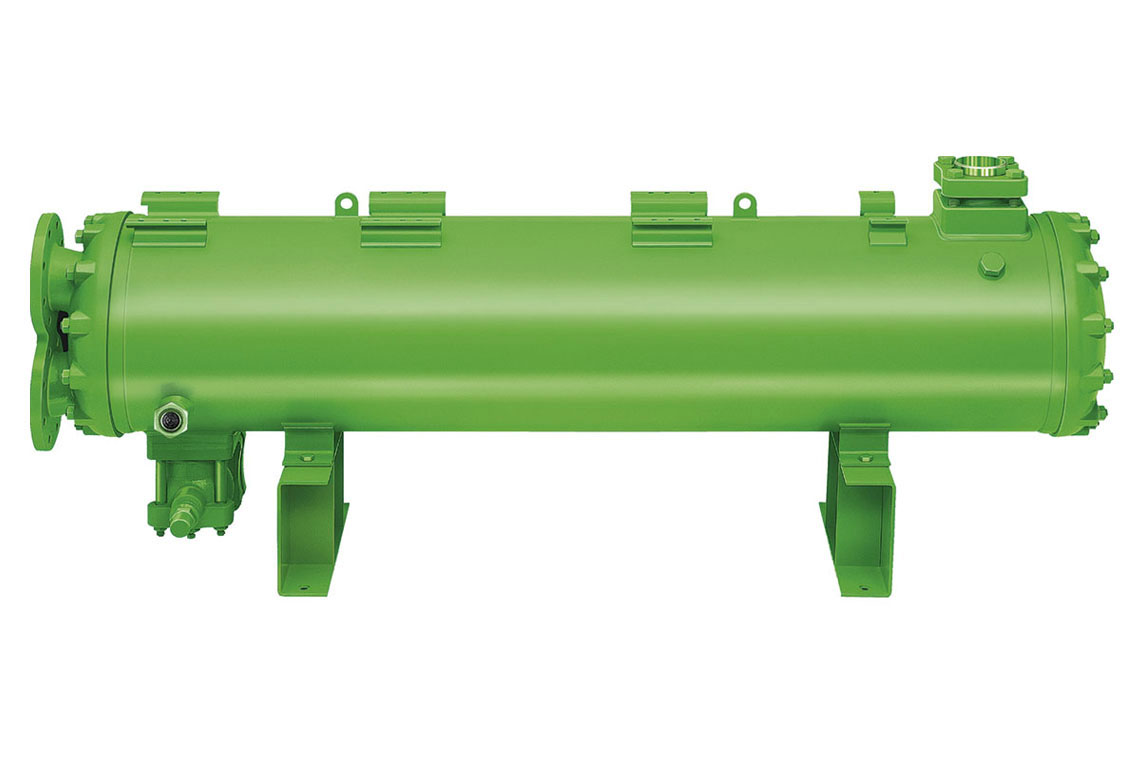

BITZER heat exchangers and pressure vessels (HEXPV) with their own trade fair stand

BITZER has been systematically expanding its HEXPV range for years. This year, a second BITZER trade fair stand was dedicated to the growing field of HEXPV and presented a powerful world premiere. The water cooled condensers for freshwater and seawater have capacities of up to 1 MW and possess the same characteristics as the proven K condensers. Their strengths include a compact design, low-fouling heat exchanger piping and high corrosion resistance. Visitors to the trade fair stand could also see high-capacity CRF compressors and powerful SQD tube bundle evaporators. The quadratic evaporators of the refrigeration and air-conditioning specialist achieve the highest efficiency currently attainable for dry expansion heat exchangers. ‘As BITZER has been developing and manufacturing environmentally friendly CO2 solutions for over 25 years, we took a decisive step and dedicated part of our HEXPV stand to climate-neutral refrigerants (GWP 1). Visitors to the trade fair stand could see our new WGC tube bundle gas coolers for transcritical CO2 applications with 120-bar design pressure and high protection against thermal and pressure-related fatigue’, says Andrea Serena, Global Manager Heat Exchangers and Pressure Vessels at BITZER.

BITZER HEXPV: progress through quality

BITZER has been systematically expanding its range of heat exchangers and pressure vessels for years, with its focus never shifting away from high quality in the process. ‘All of our HEXPV products are HFO-ready’, says Serena. ‘Our heat exchangers are also a real high-end solution.’ Having taken over the Alfa Laval SpA product segment, BITZER has become the largest independent manufacturer of shell-and-tube heat exchangers and can look back on decades of experience in dry expansion evaporators, flooded evaporators and condensers for freshwater and seawater applications with a capacity of up to 2,000 kW.

Individual solutions

With BITZER, customers can choose between proven standard HEXPV products and solutions tailored precisely to individual requirements. ‘With our project for heat exchanger and pressure vessel adjustment, we are addressing customer demands for flexible product solutions, as customer specifications are our highest priority’, says Andrea Serena. Up to five product components can be relocated from the standard position within a predefined space.

When you play the video, you transmit data to YouTube. For more information, see Data Protection

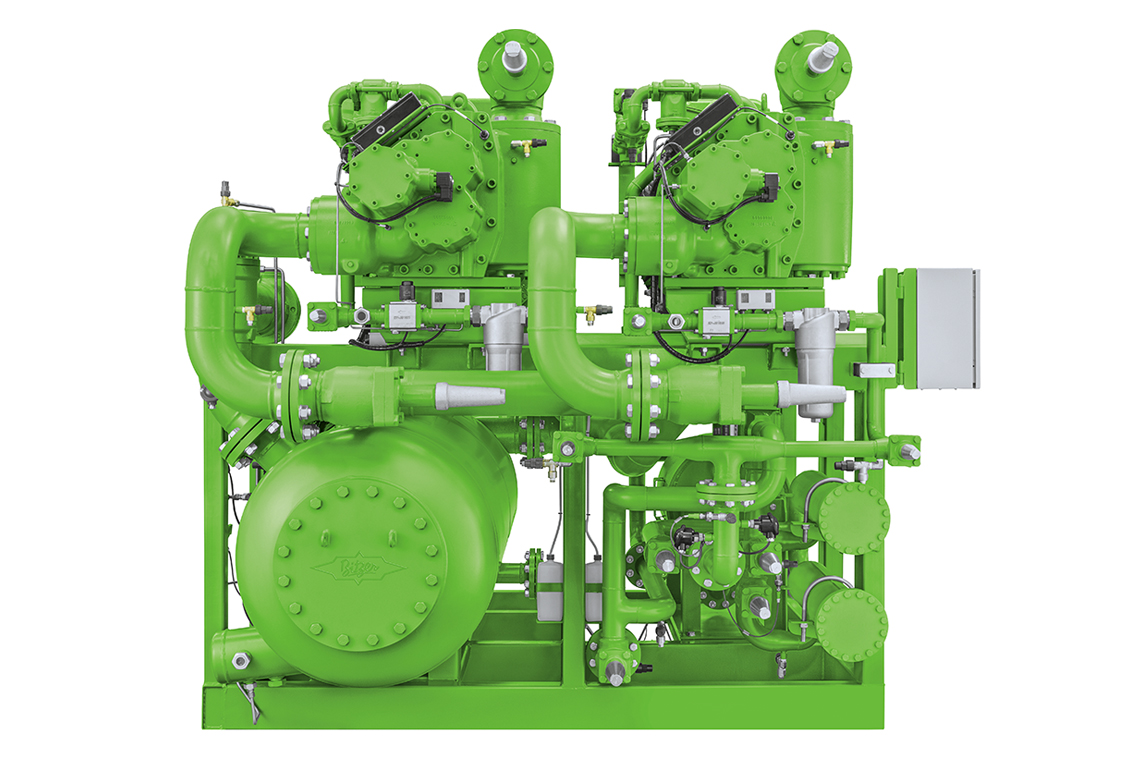

ACP – the environmentally friendly industrial refrigeration solution

BITZER has been developing and manufacturing components for ammonia applications for more than 40 years. This environmentally friendly refrigerant has no global warming potential (GWP 0) and is the first choice worldwide for industrial refrigeration. BITZER has now extended the capacity range of its products upwards with ammonia compressor packs (ACPs) and provides solutions for greater cooling capacities. The ACPs contain up to three screw compressors, motors and oil separators, with an oil circuit, control units and frequency inverters as optional extras. Ammonia compressor packs from BITZER even surpass the high efficiency and reliability standards of industrial refrigeration and achieve a cooling capacity of up to 3 MW (-10/35° C). The ACPs have an internal high pressure regulator as standard and can be fitted with many other optional components such as an economiser. Customers also profit from the low life cycle costs for which BITZER designed the ACPs especially, not to mention their simple servicing. For example, if a unit is in need of repair, all compressor components can be delivered within 48 hours.

ACP – connected in parallel and fail-safe

‘Ammonia compressor packs from BITZER provide maximum efficiency in part-load operation. This is because the internal compressors are connected in parallel and fitted with an intelligent capacity control system’, says Rainer Große-Kracht, member of the Management Board and Chief Technology Officer at BITZER. ‘With internal BITZER IQ technology, an ACP control unit then ensures efficient and reliable operation in line with the preconfigured operating conditions.’ As multiple screw compressors are connected in parallel and the control unit and most important sensors are redundant, the ACP boasts outstanding operating reliability. The precise monitoring of application limits with preconfigured parameters and alarm and shut-off thresholds provides effective protection against system failure. As soon as the alarm thresholds are exceeded, the control unit automatically initiates countermeasures and notifies the master control system. As the BITZER way of thinking and not just its branding has always been green, the refrigeration and air-conditioning specialist has developed a large number of products that can be used in environmentally friendly ammonia applications. These include OS.A95 screw compressors and OAHC oil separators.

When you play the video, you transmit data to YouTube. For more information, see Data Protection

‘There were simply too many exhibits this year for our usual trade fair stand. BITZER quality also means presenting products and services in an appropriate setting. We therefore opted to set up a second stand with an area of 58 m2 dedicated to heat exchangers and pressure vessels, which we refer to as HEXPV. The concept was a resounding success’, summarises Gianni Parlanti, member of the Management Board and Chief Sales and Marketing Officer at BITZER.