The refrigeration and air conditioning specialist is opening an additional production line at BITZER Refrigeration Technology (BRT) in Beijing, China, that will meet the same high standards of quality as in Syracuse and will focus in particular on the Asian markets.

‘In the markets for the markets, globally’ – this is what BITZER aspires to. ‘After all, no one knows what’s needed of a product better than the local users,’ reports BITZER project manager Robert Wagner. The company has been developing and manufacturing scroll compressors at its competence centre in Syracuse, USA, since 2008. The city with a population of 150,000 is approximately 315 kilometers northwest of New York City. More than 100 BITZER specialists at the centre produce scroll compressors designed for use in air conditioning and heat pump applications.

When you play the video, you transmit data to YouTube. For more information, see Data Protection

Exploiting the opportunities for growth in China

‘The global success of BITZER scroll compressors and the specific requirements of the Chinese market prompted us to set up an additional production line in Beijing,’ says Robert Wagner. ’25 years after BITZER Refrigeration Technology was founded in China, this brings us even closer to our customers here and means we now manufacture all three compressor technologies in Beijing – reciprocating, screw and scroll compressors.’

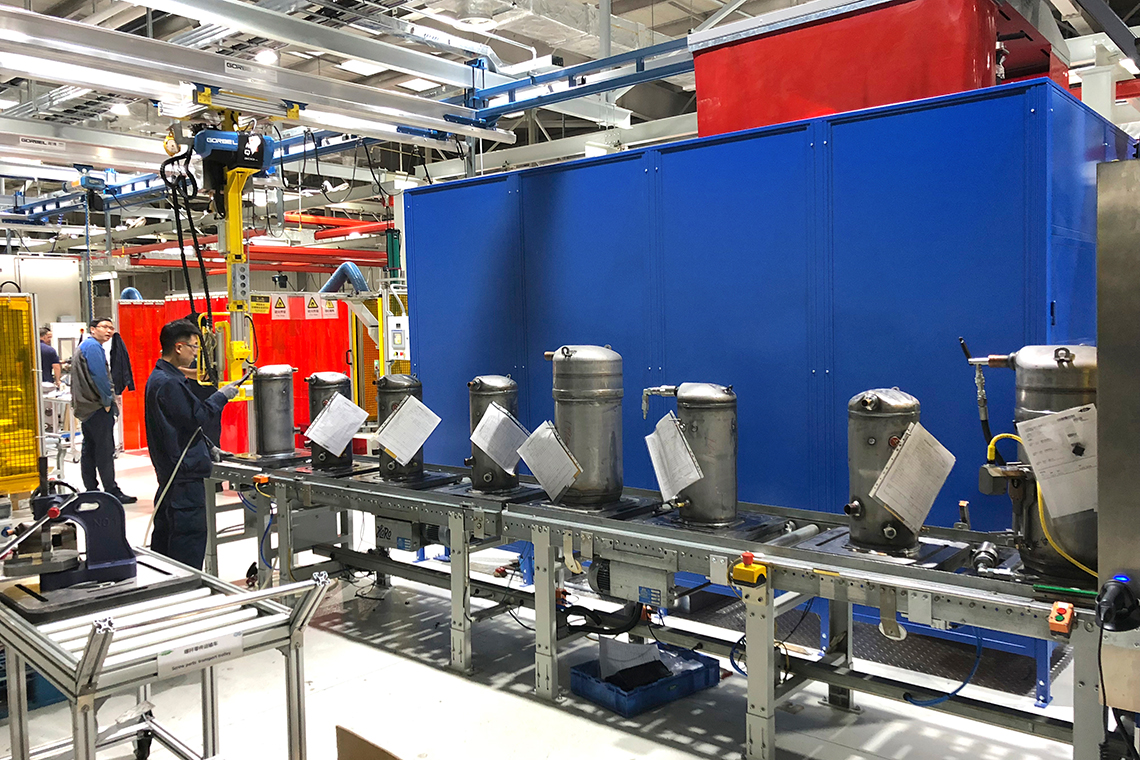

The new production line adds to the capacity available in the USA and will operate on the basis of the same production standards as the main American plant. ‘Our customers expect us to have a greater presence in China and throughout Asia with our scroll compressors,’ explains Robert Wagner. The refrigeration and air conditioning specialist decided back in 2016 to create a new production line in order to satisfy the customers and to fully exploit the market opportunities. This will now go into operation in summer 2019. ‘We have given the entire production line a modular design. This means that Beijing will initially be able to manufacture around 6,000 scroll compressors a year, and we can then gradually increase the capacity to 30,000 a year. Our aim is to corner a significant share of the scroll compressor market in China.’

’25 years after BITZER Refrigeration Technology was founded in China, this brings us even closer to our customers here and means we now manufacture all three compressor technologies in Beijing – reciprocating, screw and scroll compressors.’

Robert Wagner

BITZER Project Manager

Two sites, one BITZER Scroll team

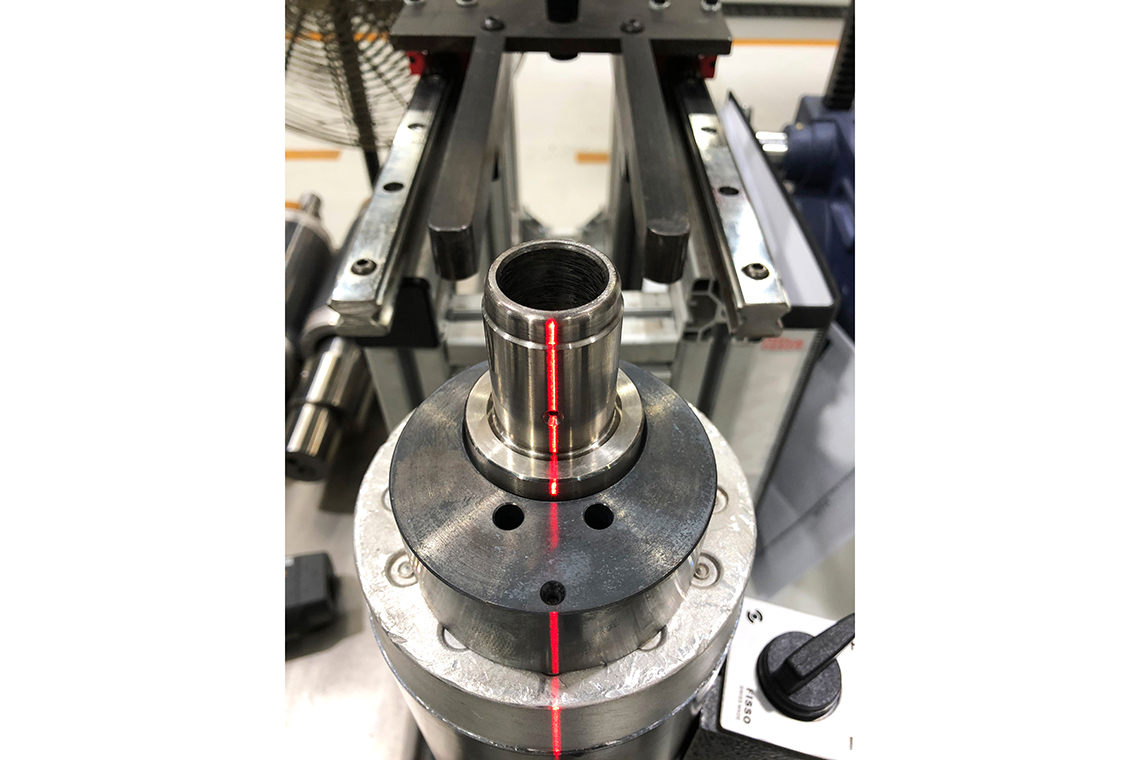

The new scroll compressor assembly line in Beijing will be subject to the same high standards of quality as in Syracuse and all other BITZER production facilities. To meet these standards, the new production facility in China has undergone a comprehensive certification process and sent seven members of staff to the USA for intensive training. BITZER Scroll gave their Chinese colleagues all sorts of valuable tips, and will continue to assist BRT with any questions that may arise. Syracuse will remain the global competence centre for scroll compressors, making it the only facility where BITZER ORBIT scroll compressors are developed. In addition, the compressors produced in the plant in New York State are for the American and European markets.

ORBIT: one compressor family, countless possible combinations

The scroll compressors manufactured on the new production line are designed for the rapidly growing Asian markets, which offer considerable growth potential. The future looks especially bright for the high-quality ORBIT scroll compressors, as BITZER developed them for modern air conditioning and heat pump applications and with all possible requirements in mind. And as ORBIT compressors can be put together in hundreds of tandem and trio unit arrangements, customers enjoy maximum flexibility and can use any system perfectly in line with their specific needs. ORBIT scroll compressors are available in the performance classes 6 and 8. In addition to the many combination possibilities, the eleven models in this family of compressors stand out in particular thanks to their high efficiency and displacement ranging from 20 to 77 m3/h (50 Hz).

When you play the video, you transmit data to YouTube. For more information, see Data Protection

‘We have given the entire production line a modular design. This means that Beijing will initially be able to manufacture around 6,000 scroll compressors a year, and we can then gradually increase the capacity to 30,000 a year.’

Robert Wagner

BITZER Project Manager

Driver of innovation in scroll compressors

With system requirements continually increasing, the refrigeration and air conditioning specialist never stops further developing its scroll compressors. Its latest innovation is the release of almost the entire product family for use with R452B, R454B and R32. This makes BITZER the first manufacturer in the world to approve almost its entire family of scroll compressors for refrigerants in the environmentally friendly A2L safety group.

The BITZER ORBIT+ scroll compressors are designed with especially efficient operation in mind. They feature a line start permanent magnet motor and boost seasonal efficiency (SEER/IPLV) by up to 8% and the refrigerating capacity by as much as 5%. They therefore comfortably meet the requirements of the Ecodesign Directive. BITZER fitted the ORBIT FIT (Flexible Injection Technology) series with an economiser that improves the efficiency of entire systems. The F-Gas Regulation and the Ecodesign Directive therefore no longer represent hurdles. The ORBIT Boreal series is suitable for especially low condensing temperatures.

Highly efficient and interchangeable whenever necessary

ORBIT compressors are highly efficient both in part and full load operation, boast high isentropic efficiency, have a broad application scope and reduce the system size thanks to their compactness. As ORBIT scroll compressors can be exchanged at any time even in compound systems, operators can continue to base their systems precisely on the capacity needed. And with BITZER VARIPACK frequency inverters, users can improve their capacity control even more.