The demands placed on refrigeration compressors are increasing. The level of complexity is rising due to new refrigerants and methods of capacity adjustment as well as the Ecodesign Directive and demand for lower energy requirements. Low-GWP alternatives to the refrigerants R404A and R507A, for example, have a higher isentropic exponent or a higher temperature glide, or even both in some cases, along with a lower mass flow. Additional cooling is therefore necessary in low temperature applications, potentially from an additional fan or liquid injection.

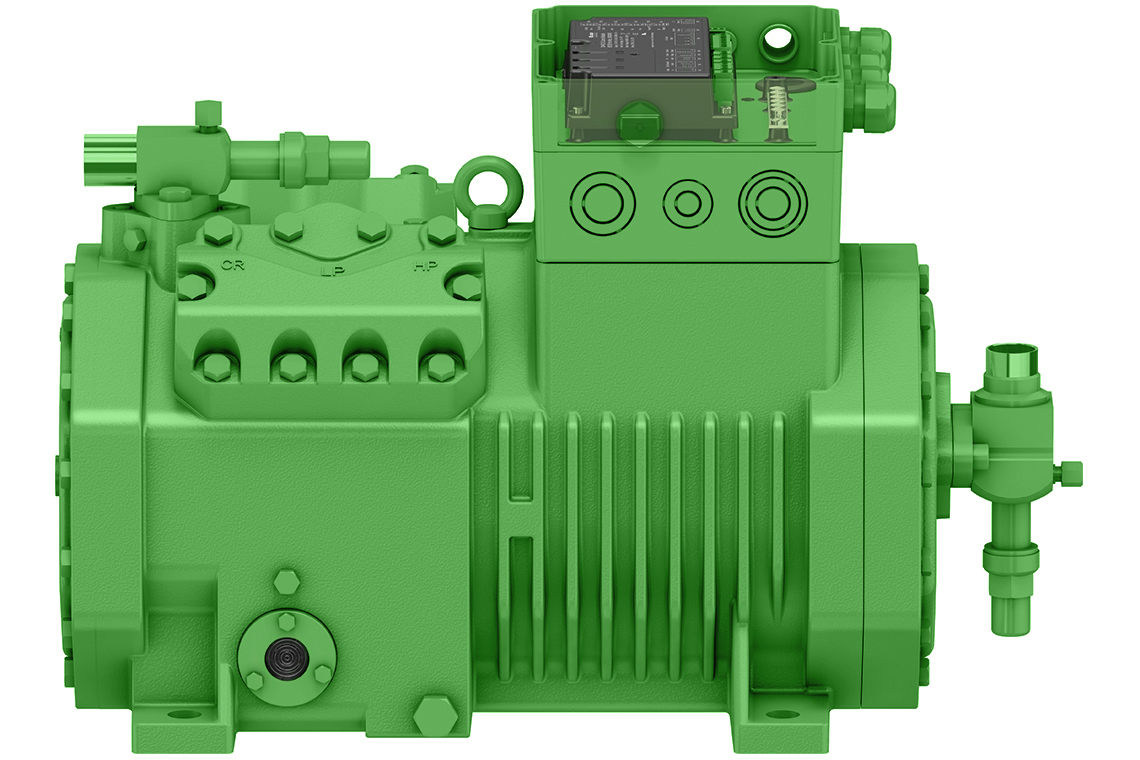

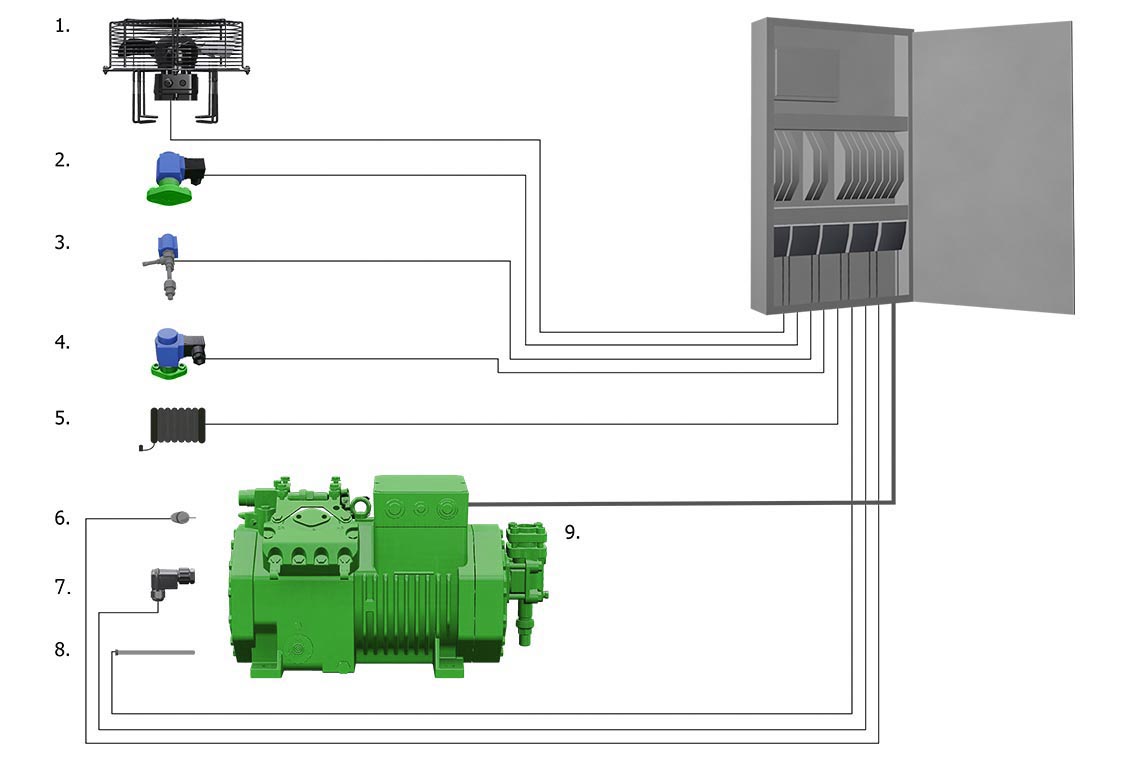

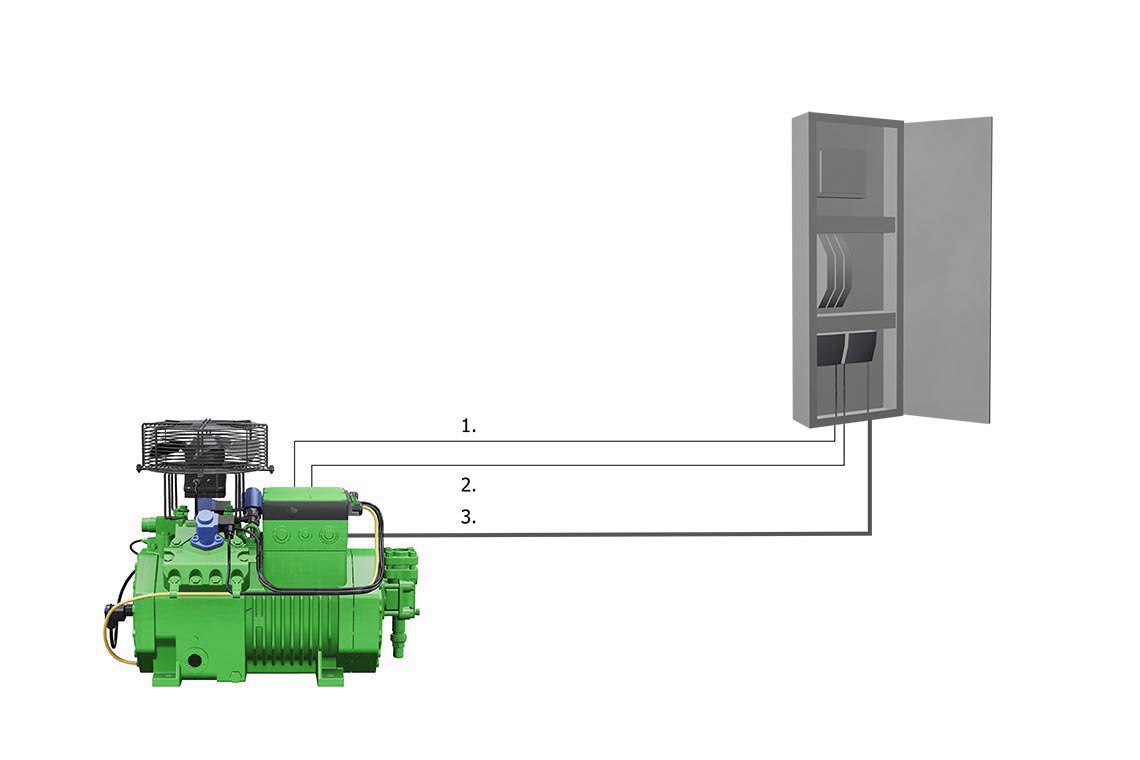

Moreover, contractors and operators previously had the problem that highly developed control systems with complex switch board configurations and custom cabling were necessary in order to deliver high efficiency and reliability. With its innovative operating concept for ECOLINE reciprocating compressors with built-in IQ modules, BITZER has developed a highly efficient, compact solution to this problem.

Simply convenient – the IQ module from BITZER

The IQ module from BITZER offers the decentralised operation of compressor-fitted functions such as capacity control, additional cooling and the oil heater. ‘It also monitors the oil level and pressure and the discharge gas and motor temperature and can even monitor the application limits of the compressor,’ says Dr Armin Walz, Head of Application Engineering at BITZER. ‘This allows the compressors to operate safely and with optimal efficiency throughout the entire application range. At the same time, the IQ module increases the availability of the system. Only a run signal for the compressor and 0–10 V capacity control are required. With just one switch board configuration, a range of different system variants can be realised quickly, effectively, affordably and flexibly.’

With the IQ module, BITZER is also dramatically simplifying the cabling of the individual components. ‘The reduced system complexity also lowers the potential for faults. This also decreases the costs of materials and personnel for system operators,’ explains Dr Walz.

BITZER IQ module: a new operating concept for reciprocating compressors

When you play the video, you transmit data to YouTube. For more information, see Data Protection

Low costs and high efficiency – the IQ module and VARISTEP

‘The IQ module improves the efficiency of systems considerably,’ states Dr Walz. ‘The newly developed logic facilitates the optimal use of the virtually stepless VARISTEP capacity control. And that has a positive effect on system efficiency and operating stability.’ With this mechanical control system, the cooling capacity can be adjusted based on the actual requirements quickly and easily with a modulation range between 10 and 100 per cent.

The benefit of the small capacity steps is that users can cover the wide load ranges of systems with precision. This minimises control deviations in the system suction pressure and lowers the energy consumption compared to systems with more basic capacity control steps or without capacity control altogether. Another benefit of the IQ module is that if thermally necessary, the IQ module automatically switches on optional components for compressor cooling, such as refrigerant injection and an additional fan.

‘The IQ module also monitors the oil level and pressure and the discharge gas and motor temperature and can even monitor the application limits of the compressor.’

Dr Armin Walz

Head of Application Engineering at BITZER

Use of low-GWP refrigerants

‘With the IQ module, BITZER is also expanding the application limits of the ECOLINE series for the refrigerants R407A, R407F, R448A and R449A. This is possible due to the improved refrigerant injection as well as the optimised interaction of operating and protection features. Using the free BEST software and the IQ module, users can configure their compressors to work with the chosen refrigerant quickly and easily,’ says Dr Walz. With the BEST software, operating data, counters and statistics can even be displayed graphically and listed in tabular form. The database in the BEST software covers all the refrigerants available in the BITZER software. The operating concept is clear, intuitive and extremely user-friendly.

Pre-fitted with the IQ module

Users can have all compressors in the BITZER ECOLINE series pre-fitted with the IQ module and wired accessories. For wholesale trade, different variants of special add-on kits are also available to easily fit standard compressors with the IQ module and accessories selected by the customer.