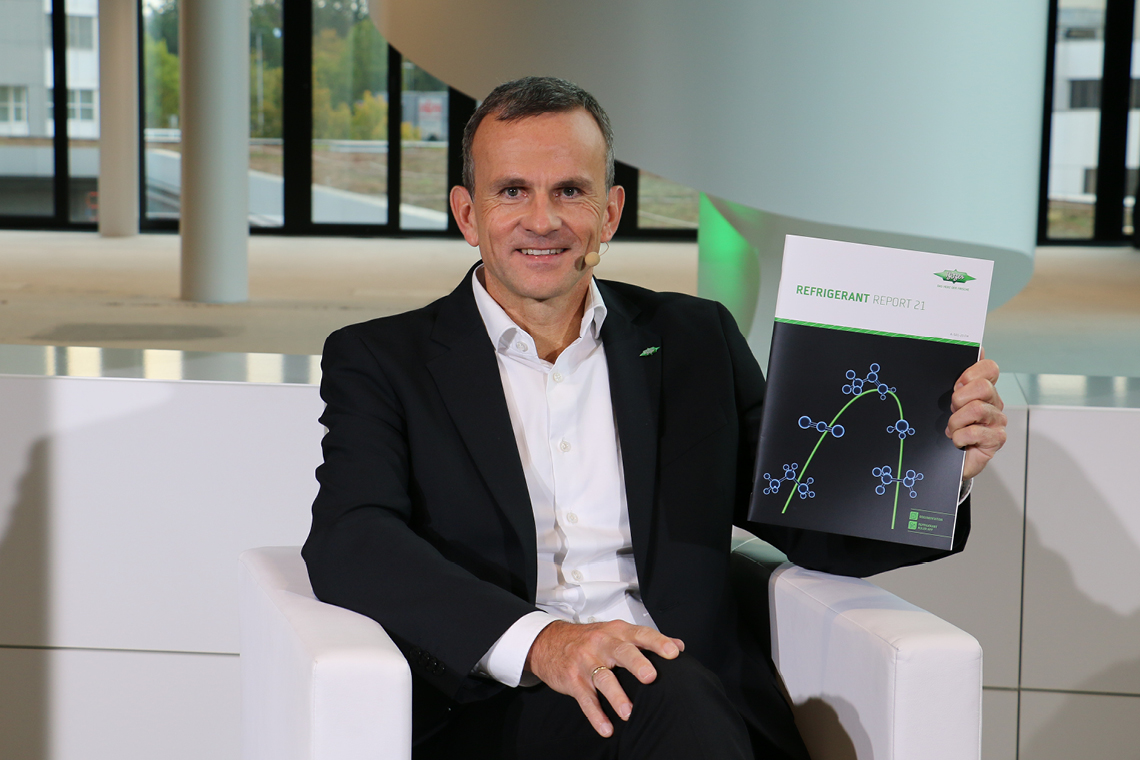

On 29 and 30 September, our experts Hermann Renz, Technical Programs Manager, Dr. Heinz Jürgensen, Director Application Engineering and Product Performance, and Julian Pfaffl, Head of Product Performance, discussed the topic of refrigerants in three livestreams and presented exclusive insights into the new BITZER Refrigerant Report 21. The live event was moderated by Volker Stamer, Director of the SCHAUFLER Academy.

We received many questions, so our experts unfortunately couldn’t answer all of them during the live discussions. Therefore we have listed the most important questions about the latest refrigerants with their corresponding answers here.

The tolerance range for GWP calculation is already considerable. IPCC Report IV estimates it to be around ±35 per cent and states that the direct greenhouse effect of the decomposition products is insignificant and that further processes could only be estimated with a great deal less certainty.

BITZER is closely following the development of R469A in the ultra-low temperature application. Layouts for R469A and application recommendations can be obtained directly from BITZER branches at any time. There are no plans at present to incorporate it into our selection tool, the BITZER Software.

We’re not aware of any official statements on this issue.

It’s important to clearly differentiate between weather-resistant enclosure and a machinery room. Installation a short distance from the building which requires cooling can make sense from a technical point of view and may also be required by the insurance to better protect the refrigerated goods, even if it is not required by refrigeration system standards. This is a risk assessment for applications which extend beyond system and device standards.

The EN60335-2-34 standard outlines a whole host of safety measures related to the use of flammable refrigerants, without a lower volume limit. Flammability has even been assessed and additional tests carried out for a refrigerator with 19 g R600a.

Our ECOLINE P semi-hermetic reciprocating compressors are approved for use with propylene (R1270) and propane (R290). You can find all the relevant information here.

Our semi-hermetic ECOLINE P series is approved for propane (R290) and propylene (R1270). On request, our HS semi-hermetic screw compressors can also be used with R1270. Please contact BITZER for more application information.

R448A and R449A have a higher isentropic exponent and thus a higher discharge gas temperature than R404A. The first step would be to recalculate the compressor with the BITZER Software and the new refrigerant with the highest condensing temperature expected and check the discharge gas temperature.

If the application limit suggests additional cooling or the discharge gas temperature exceeds 140 °C, a cylinder head fan or a refrigerant injection (RI) with CM module can be used. Further information and a complete manual are available here.

Since the launch of R134a, we as an industry have been following publications and research on decomposition products such as trifluoroacetic acid. Based on our current state of knowledge, there are some bodies of water around the world without drainage and with high levels of evaporation which could lead to accumulation over a period of decades and thus serve as indicators that measures need to be taken.

We’re not currently aware of any technically or environmentally significant reasons why these substances should not be used. They’re an important tool in the reduction of greenhouse gas emissions (expressed in CO2 equivalents) and will hopefully be available for long to come. We welcome continued discussion and the arrival and evaluation of new studies and their findings.

This discussion likely derives from concerns about follow-up costs resulting from plausible forms of damage. Thank goodness for positive experiences like these, as it will take more and more systems with R290 and other hydrocarbons to protect the environment. We also need to develop a foundation of experience in the safe use of hydrocarbons.

According to the ASHRAE34 data sheet of R470B, it is a mixture of six components, including CO2, and has a temperature glide of over 30 K at ambient pressure. With this temperature glide, we consider it very difficult to build functional and efficient systems and don’t see a wider use in practical applications.

There are different possibilities to ensure safe operation of systems that contain A3 refrigerants. In appliances and, depending on the operation site, small commercial systems, gas sensors might not be necessary. The necessity is a result of the safety concept and risk assessment the manufacturer and operator make.

NH3 is one of the most efficient refrigerants and there are no reasons not to use ammonia in industrial applications. We support this with the recent development of our Ammonia Compressor Pack (ACP) and the development of larger ammonia compressors especially for industrial applications. Beside ammonia, R744 compressor racks can also be an efficient solution in this kind of application.

R448A/R449A have a higher isentropic exponent and therefore a higher discharge temperature compared to R404A. The first step would be to recalculate the compressor performance in the BITZER Software under the highest expected condensing temperature and check the discharge gas temperature with the new refrigerant.

If the application limits suggest additional cooling or if the discharge temperature is above 140 °C, an additional fan for cylinder cooling or the RI refrigerant injection with CM module can be used. See this retrofit guide for more information.

The ECOLINE H series will be extended to a condensing temperature of 95 °C and evaporating temperature of 35°C for R1234ze(E). With this refrigerant, no further extension will be possible due to the high level of discharge pressure and operation close to the critical temperature. For higher condensing temperatures, R1233zd(E) could be a solution. Please contact BITZER for further information.

Large industrial plants will often have a large refrigerant charge. And a good design is always necessary for a large plant. When choosing refrigerants, their availability for use in these applications in the long term has to be considered – they should be available for at least 30 years. Large amounts of R717 (ammonia) or R290 (propane), for example, might be restricted for use, depending on the surroundings of the system.

There are a few substitutes for R22 in flooded systems. Alternative refrigerant mixtures always have the danger of segregation of single components in flooded systems. R134a seems to be a reasonable solution but requires larger compressors for the same cooling capacities.

In marine medium temperature applications with DX evaporators, we can mainly observe the use of R407C as it can also be applied in the air conditioning systems and is highly available. This is because lower GWP alternatives such as R134a or R513A can be efficiently applied in MT refrigeration systems but the systems will become a bit larger.

R729 (air) and R718 (water) are probably the most natural refrigerants but are not generally feasible for the typical applications in the scope of the Refrigerant Report. The Report does not claim to cover all potential refrigerants – its focus is on commonly used refrigerants and their alternatives for stationary refrigeration, air conditioning, heat pump applications and ORC cycles.

Of course, there is also potential for the use of R718 or R729 in very specific systems, which are mainly to be seen in niche segments, however. But even there the required engineering know-how, system technology and the application as such are very demanding and suitable system components are not available on a broader scale.

Incidentally, R729 became more commonly known at the time it was applied in the German ICE 3 high-speed train in the passenger-car air conditioning systems. Studies showed that the energy demand under these particular conditions is two to three times higher in comparison to traditional vapour compression cycles (Die Kälte & Klimatechnik Issue 6/2004).

Air as a refrigerant (R729) could be used, for example, in ultra-low temperature applications. However, we’re not aware of any verifiable sources which can prove that air as a refrigerant is as efficient in low temperature systems and other applications as it is in compression refrigeration systems.

BITZER tested R466A in its GSD scroll compressors to check the efficiency and material compatibility but has not released the compressors for R466A. R466A contains CF3I which is a halomethane containing iodine. This leads to a small ODP. The iodine is also known to be highly reactive in combination with alloys and lubricants.

Many thanks!

I will wait for an answer.

I wrote to you because several years ago I was trained at SCHAUFLER Academy and I really liked the level of equipment of the Academy, the high level of staff and the quality of training.

Aleksandr Bambiza,

RAC Association APIMH,

Belarus

Dear Aleksandr, Thanks for your request. We don’t understand exactly what you mean. Our colleagues from Russia are going to contact you and discuss it in detail. Have a nice day! Your BITZER Team

Dear friends,

could you help me?

I can not find information about installing double plates of discharge valves (two plates on top of each other) on 4DES-7Y-40S BITZER compressors. Is it possible?

Aleksandr Bambiza,

RAC Association APIMH,

Belarus

Dear Sir or Madam, Thanks for your request! Please have a look the BITZER product range: https://www.bitzer.de/shared_media/documentation/a-205-6.pdf You’ll get more information on our website as well: http://www.bitzer.de

Hello! Can you give me more information and documents on the application range of the manufacturer’s compressors?