It was in the early summer of 2019, when Hotel Alsik opened its doors to the first guests at the waterfront in Sønderborg, Denmark. The construction of this 19-storey hotel, plus restaurants and spa area, is part of a big development project involving Sønderborg’s waterfront, with the hotel supporting the town’s vision of being CO2-neutral by 2029. Here the focus is firmly on sustainability and high quality. For this reason, Alsik is also acting as a showroom for the special Clean Tech expertise of the companies in the Sønderborg area. One of them is BITZER.

Focus on quality

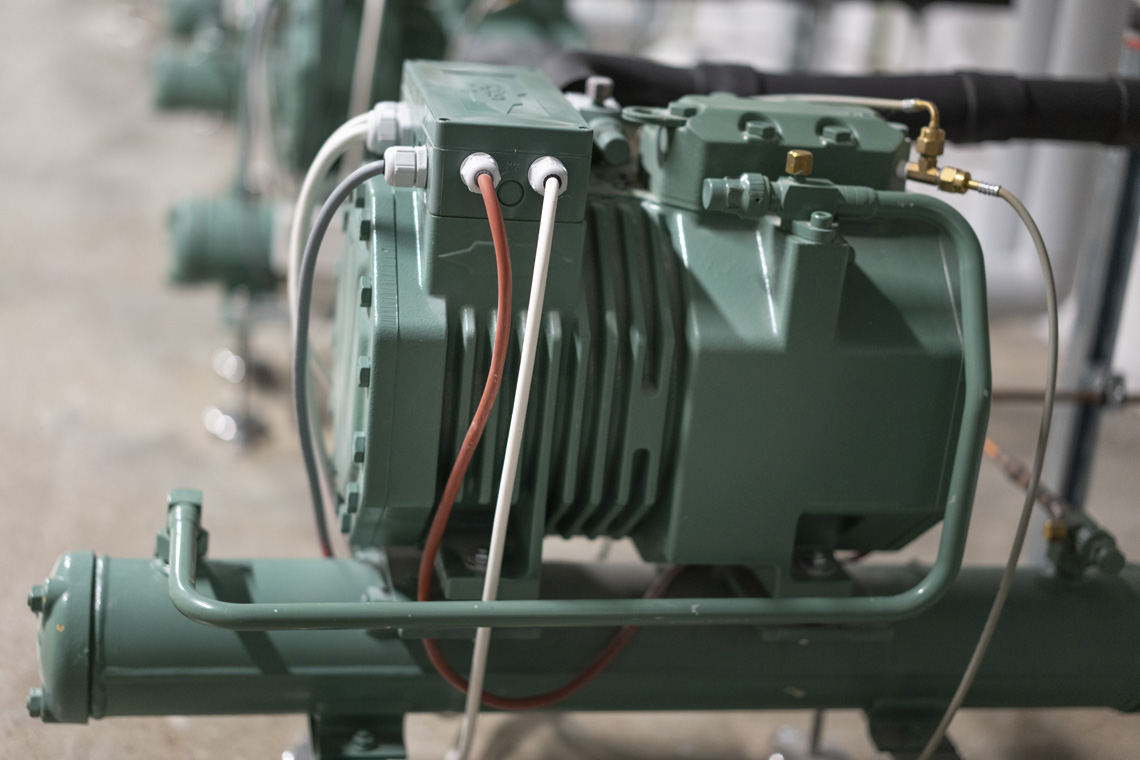

From the cellar to the attic space, Hotel Alsik never fails to use materials of the highest quality. The cellar is the place where a large refrigeration system ensures cooling of ten different cold stores and freezer rooms across different locations. The water-cooled condensing units are an optimal matching unit program with effective and robust compressors and condensers. The system includes ten BITZER ECOLINE semi-hermetic reciprocating compressors with water-cooled shell and tube condensers from the BITZER K-3 series. Together they ensure the correct temperatures in the various kitchens, cold stores and freezer rooms of the hotel. At the same time, the BITZER solutions also ensure a high refrigeration capacity, a high performance level and lower energy costs. The design of the compressors allows the use of low-GWP refrigerants like R449A and R513A.

The components were supplied by the wholesaler H. Jessen Jürgensen A/S and fitted by the company Climate A/S. Carsten Pedersen, Sales Engineer at H. Jessen Jürgensen, reports: “A project like Hotel Alsik is a perfect example for cold storage and freezer rooms. Here the focus is on sustainability, quality and performance which are the basis for the right solution with quality products from the start. As a refrigeration wholesaler, it’s a pleasure for us to work with customers like Climate who appreciate the value of the technical support our product specialists offer them.”

Michael Kurth, Facility Manager at Hotel Alsik, has the daily job of supervising all the cold stores and freezer rooms, which also includes several wine cabinets in both the cellar and on floor 18: ‘It’s easy to see that quality was very important when Alsik was built. That’s clear from our large refrigeration system as well. It has worked from day one, and we haven’t experienced any complications whatsoever,’ he states.

At the moment, heat is transferred from the closed refrigerating circuit to a free cooler. In the long term, Hotel Alsik would like to exploit this heat and make use of it in a heat pump for domestic hot water or space heating, for example.

Assembly and service

Climate, the company that installed the system in 2019, is pleased to report that the project was a success: ‘In terms of quality, we’re talking about a really high level, and this solution is the perfect one in that sense,’ emphasises Jørgen Ludvigsen, Sales Manager at Climate. The system’s design will also make it easier to troubleshoot in the future. ‘The way in which the system is designed, constructed and positioned means not only does it look great, but also that it is easier for our technicians to provide the correct service. It’s easy to access and it’s clear how the individual components are connected,’ continues Jørgen Ludvigsen. Climate received confirmation of the order in November 2017 after a bidding process for the contract in collaboration with major kitchen supplier Bent Brandt A/S.

As an independent specialist for refrigeration and air conditioning technology, BITZER is present all over the world: with products and services for refrigeration, air conditioning and process cooling as well as transport, BITZER ensures optimum temperature conditions for trade in goods, industry processes and indoor climate control – always considering highest possible energy efficiency and quality. BITZER is represented all over the world with 72 sites in 37 countries, including its sales companies and production facilities. Trade and service partners included, the BITZER network of manufacturing, development and sales extends to almost all countries in the world. In 2019, 3,800 employees generated a turnover of €808 million; expenditure for research and development totalled €46 million.